Manufacturing students benefit from Brandywine, LMC partnership

Published 5:07 pm Tuesday, September 25, 2012

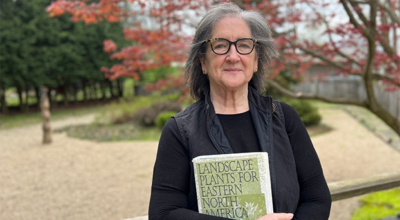

Students, school staff and members of the community mingle prior to the grand opening of the new and improved machine-tool shop at Brandywine High School Tuesday afternoon. Leader photo/CRAIG HAUPERT

Brandywine High School junior Nathan Anders knows what he wants to do when he’s done with school.

He wants to work as a precision engineer.

And thanks to a partnership between Lake Michigan College, Brandywine and Berrien RESA, Anders knows how to turn his goal into reality.

“Without this being here, I would be lost,” Anders said. “I wouldn’t even know where to start.”

Anders is one of several students taking part in a program designed to prepare students for careers in manufacturing. The program — officially unveiled during a ceremony Tuesday at Brandywine High School — provides training and early college credit opportunities for high school students, while offering degrees and certificate programs for college students.

To accommodate the program, LMC moved 19 mills, lathes and surface grinders from its Bertrand Crossing campus in Niles to Brandywine High School’s existing machine-tool shop. A new classroom was also added next to Brandywine’s machine-tool shop.

Brandywine and LMC will share the space, equipment and instructors. High school students will use it during regular school hours and college students will use it in the evening.

“It’s a good thing for the students. It’s a good thing for the college; it’s definitely good for Brandywine,” said Chris Inman, who teaches machine-tool classes at LMC and Brandywine. “We work with a lot of companies and most of these guys will be offered a job with a company, and the majority of those will be offered an apprenticeship, which in many cases pays for college.”

Nick Fulbright, owner of Great Lakes X-Cel, a Niles manufacturing company, said he is happy to see this program up and running.

“We have experienced for some time a lack of a talent pool we can tap to get people starting in manufacturing in all different phases,” Fulbright said. “We came to the conclusion a couple years ago in order to get these people trained we’d have to raise them in-house. This program can only help.”